What Is Dieline Box In Packaging & Printing?

Discover how box dielines shape perfect packaging. Learn how dieline templates help in folding, printing, and building boxes that match your product style and fit by reading this amazing blog post.

When you open a product, have you ever thought about how the box was made? A lot of planning goes into that. Before a box comes to life, it starts as a flat shape. That shape is called a box dieline. From toy boxes to food boxes, all need a dieline. Many famous brands trust dielines to help get boxes right the first time.

This blog discusses what a box dieline is and how it is used in packaging and printing. You’ll learn how a flat design turns into a real box. We’ll talk about why it matters, who uses it, and where it fits in the printing process. Ready to see how packaging begins? Let’s start.

What a Dieline Really Is?

Box dieline shows where to fold, cut, and glue. When you see it, it looks like puzzle pieces that make a box. It’s made before anything is printed. Designers use it to plan. Printers use it to cut. This flat map helps turn paper or cardboard into a real shape. Without it, you might fold the wrong way. Or glue the wrong part. So, it helps avoid mistakes. Many types of boxes start this way, like snack boxes, game cards, and even pizza boxes.

Why Dielines Are So Important?

Without a dieline, your box might not work. It may not fold or close right. It might tear or not fit the product inside. A dieline packaging template saves time and money. It helps brands check the design before printing. If something is wrong, it can be fixed early. It also shows the print area. That means designers know where to place pictures, text, and logos. This makes the box look great when finished. The team at The Custom Boxes always checks dielines to get a perfect box each time.

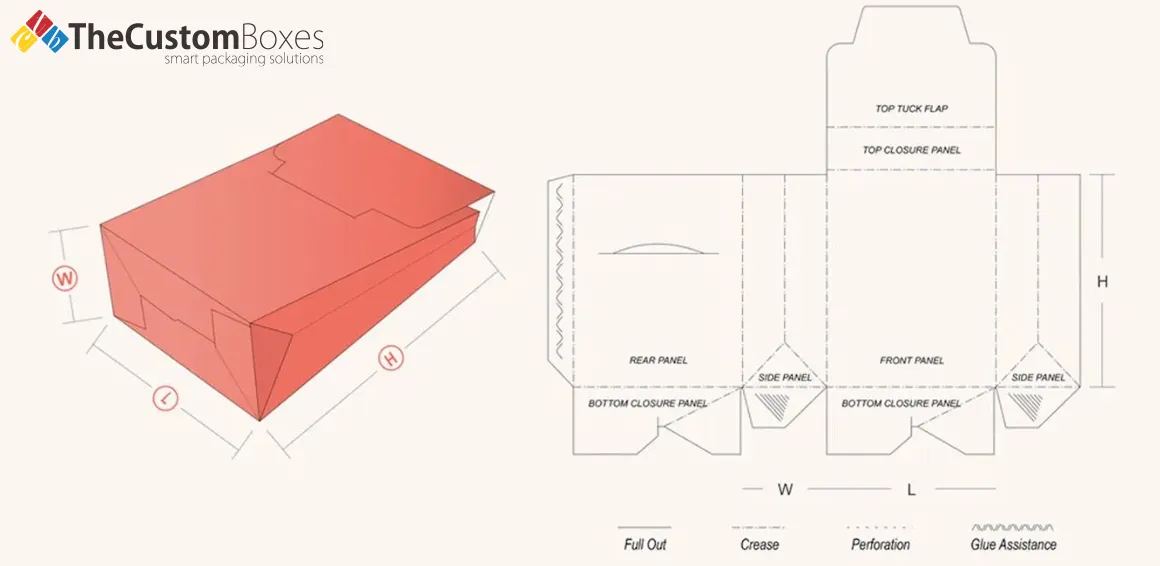

What a Box Dieline Looks Like?

At first, a cardboard box dieline may look confusing. But each line has a job. Straight lines show where to fold. Dotted lines may show cuts. Tabs are added where glue will go. Some dielines are big. Some are small. Designers use computer programs to create dielines. They then send them to printing companies to use. Our company uses smart tools to create dielines that match each customer’s box perfectly.

Dielines For All Kinds Of Boxes

Different boxes need different dielines. A box for cards won’t look like a food box. Each product has its own shape. For example, a playing card box dieline is small and neat. It holds cards in a tight space. It needs to fold just right to keep the cards in place. A pizza box dieline is large and flat. It needs to open wide but hold strong. It also keeps food warm while looking neat. Our experts have made dielines for toys, snacks, soaps, and more. Each one is made to fit the item inside.

How Dieline Printing Works?

Dieline printing means printing the design based on that flat map. Printers use the dieline as a guide. They cut, fold, and glue based on those lines. It ensures every box is the same. Designs are added to the dieline, too. That way, nothing is off-center or cut wrong.

How a Good Dieline Helps Brands?

For brands, first looks matter. A box with bad folds or colours can scare off customers. A good dieline helps boxes look neat and professional. It helps with shipping, too. A flat box is easier to pack and send. And if it’s folded just right, it’s stronger. Boxes made from well-made dielines are also easier to store and stack. The Custom Boxes focuses on clean dieline work to help brands look smart and ready.

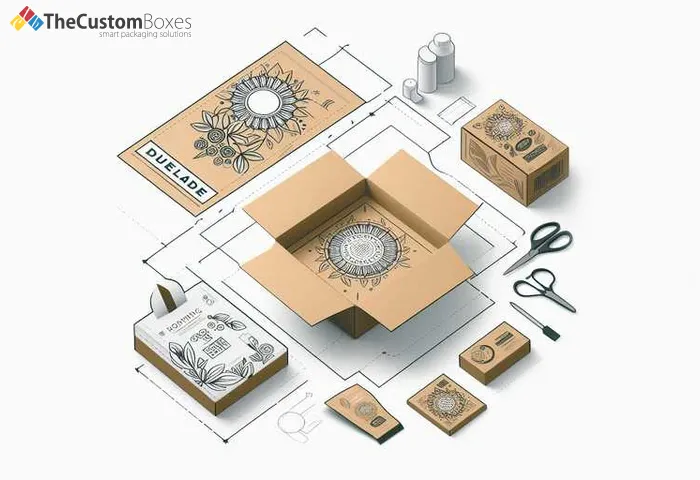

Making A Custom Dieline

Every product is different. So, its box should fit just right. That’s where a custom dieline helps. A cardboard box dieline can be shaped in many ways. Square, tall, skinny, wide, each item needs the right fit. With the right measurements, designers can draw the exact shape. Our team works with each brand to build boxes that look good and feel strong.

Mistakes To Avoid With Dielines

Sometimes, people forget to leave space for folds. Or they don’t line up the logo. These small errors cause big problems. That’s why dieline packaging must be done with care. You need to think about glue, space, and size. Even print colours may shift if the design isn’t in the right spot. Good dielines help stop these issues. The skilled hands at The Custom Boxes check every dieline to make sure it fits and folds just right.

From Flat Sheet To Final Box

After printing, folding, and gluing, your flat dieline becomes a box. It can be opened, closed, and stacked. When customers see your box, they see care and style. That’s why getting the dieline right is so key. It’s not just paper. It’s your brand’s first voice. We build custom printed boxes that go from flat to fab with ease.

How Dielines Help All Businesses?

Big or small, all businesses can use dielines. Even custom pizza box dieline layouts help local food places shine. Just keep the file and reuse it. Our service helps keep these files safe so that you can print again anytime.

Wrap-Up: Design Smarter With Dielines

A box dieline may look flat, but it holds big value. It helps you shape, print, and design your package with care. You need it to plan folds and prints. You need it to save time and money. Most of all, you need it to give your product a box that feels just right. To get clean, smart dielines made just for you, buy your boxes from The Custom Boxes. We don’t want you to be left waiting, so we immediately send your order. We have the fastest shipment services around to ensure our customers aren't waiting. And don’t worry, all standard orders come with complimentary shipping. We will immediately start the work when you send us your design. We deliver your order promptly while never reducing the quality. Our friendly team is ready to bring your dream box to life, starting with the perfect plan.