What Are Different Types Of Packaging Tapes? The Custom Boxes

Discover the different kinds of packaging tapes for different boxes or items. Learn about acrylic and rubber. Also, solvent-based tapes. Its uses and strengths. Green-friendly choice to keep your packaging clean and secure for shipping, storage, or retail.

Packaging tapes play a big role. We give different tapes for different needs. Acrylic tape is low-cost and works well in normal weather. Hot melt tape is strong and sticks quickly. Water-activated tape bonds with the box and adds security. Masking tape is good for light packing and labels. Filament tape has fibres and supports heavy cartons. Double-sided tape gives a clean finish for displays. PVC tape is smooth and quiet to use.

The Custom Boxes designs unique types of packaging tapes. Choosing the right tape helps prevent damage and keeps parcels secure. In this amazing article, we are going to discuss the different types of Packaging Tapes.

Why Packaging Tapes Matter In Shipping And Storage

Packaging tapes are used to reduce damage and loss. Different tapes suit different needs. Some tapes work best for heavy boxes. Others are good for light parcels or short storage. Good tape also makes stacking easier in warehouses. It helps keep boxes neat and stable. In shipping, clear tape can show labels clearly. Printed tape can show warnings or brand names. Poor tape can fail and cause problems. That is why packaging tapes matter. They support secure transport, organised storage, and reliable delivery from start to finish.

Role Of Packaging Tapes In Product Safety And Parcel Integrity

Packaging tapes play a key role in product safety and parcel integrity. They keep boxes closed during shipping and storage. Strong tape stops cartons from opening while handled. It helps boxes stay firm when stacked. Clear tape keeps labels easy to read. Using the right tape helps parcels arrive safely and in good condition.

How Different Tape Types Serve Different Packaging Needs

Different types of packaging tape use many purposes.

- Acrylic tape is low-cost.

- Hot-melt tape seals heavy boxes quickly.

- Masking tape is best for labelling or tiny packages.

- Filament tape supports wholesale boxes.

- Double-sided tape is good for displays.

- PVC tape is sustainable.

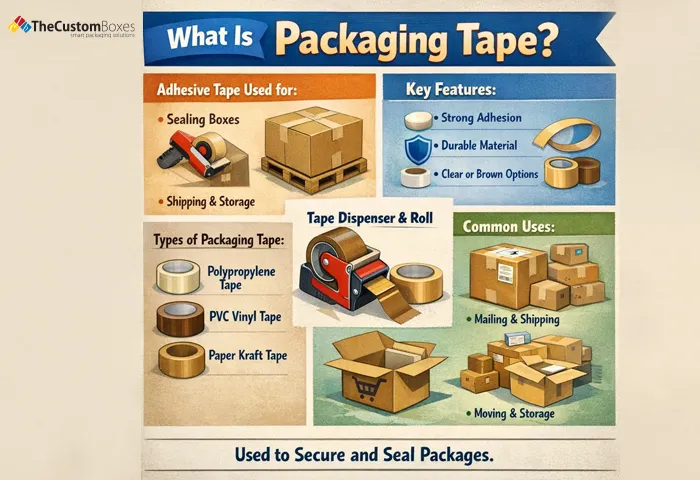

What Is Packaging Tape?

Packaging tape is good because it works as a protective shield for your items. Without the right tape, boxes can open, leading to damage. It works with security, as it makes tampering easy to spot. By using higher-quality tape, you ensure your parcels stay secure.

Primary Functions

Packaging tape is a stronger adhesive used to wrap and reinforce boxes for storage. Its primary function is to keep your products safe. The tape acts best protective shield against dust and moisture. It provides structural strength to prevent heavy boxes from bursting open. By using the right tape, you ensure your items reach their best condition.

How Packaging Tape Supports Sealing, Bundling, And Protection

Packaging tape helps in protecting items. It keeps boxes closed during shipping. Strong tape bundles many packages safely. Clear tape keeps labels comfortable to read.

Common Industries In The UK That Rely On Packaging Tapes

Do you know which British industries depend on high-quality packaging tape every single day? In the UK, E-Commerce and Retail are the biggest users, shipping millions of parcels for home delivery. Manufacturing firms need strong seals for shipping heavy components, while the Removal and storage sector uses tape to keep household items safe during moves.

Key Factors That Differentiate Packaging Tapes

The packaging tapes differ in multiple ways. The material is very best like polypropylene. Adhesive kinds matter too, such as acrylic and rubber. Width and length change usage.

Adhesive Type (Acrylic, Rubber, Solvent-Based)

Acrylic tape is water-based option. It works well in cold weather and does not change its colour. Rubber adhesive, often called hot melt, is famous. It pastes to cardboard, making it great for fast packing. So, solvent-based tape is powerful. It works well with humidity, making it a good selection for heavyer duty shipping.

Backing Material (Plastic, Paper, Reinforced Fibres)

The tape backing material determines its strength. For very heavy items, use tape with reinforced fibres. These contain glass strands that prevent the tape from snapping. Always select the material based on the right weight of your packet and your environmental goals.

Strength, Durability, And Temperature Resistance

Tape performance depends on three factors. Temperature resistance is best for storage. Always check and ensure your boxes stay securely until they reach their location.

Environmental Considerations And Recyclability

Environmental considerations are best in packaging. Most tapes use plastic, which can harm the Earth. Recyclable tapes are a good option. Paper-based tapes are easily recycled. Nature-friendly tape supports durability. Reducing packaging waste protects Earth.

Common Types Of Packaging Tapes

There are several common types of packaging tape used in the UK. Polypropylene is the most popular choice because it is strong and very affordable. For a greener option, paper tape is best to recycle and sticks perfectly to cardboard.

Acrylic Packaging Tape

Acrylic packaging tape is a lower-cost choice. They uses water-based adhesive that stays clean. It handles temperature changes well. It provides the best lasting protection.

- Characteristics And General Use Cases

Packaging tape has many uses. Its job is to seal the seams of cardboard boxes to keep products secure. You use it to bundle loose produce.

- Performance In Varying Temperatures

Packaging tape must work in different temperatures. Cold weather can make some tapes lose stickiness. Hot conditions can soften the adhesive and cause slipping. Special tapes are made to handle heat or cold. Acrylic adhesive works fantastically in different climates. Rubber adhesive pastes work well in cold places. Choosing the right tape helps packages stay sealed. Good temperature performance reduces damage during storage and transport.

Hot Melt Packaging Tape

Hot melt packaging tape is the best option for busy warehouses. It is best for fast-paced packing lines. It is strong and works best on recycled boxes. It can sometimes be tricky to seal. While it can be a bit noisy to use, it provides a very secure, permanent bond.

- High Tack And Quick Adhesion Properties

High tack means the tape sticks quickly when applied. Quick adhesion saves time during packing. The tape grips the surface with light pressure. This is helpful for fast work. It also works well on rough or dusty boxes. Strong initial stick keeps cartons sealed. High-tack tape reduces the need for extra layers.

- Suitability For Heavy-Duty Sealing

The tape must hold heavy boxes securely. Thick backing adds extra strength. Strong adhesive prevents cartons from opening. It should resist tearing under load. Good tape also handles rough handling. This is important during transport and storage. Heavy-duty tape keeps items safe. It reduces damage and returns. Choosing the right tape improves packing quality and reliability.

Solvent-Based Packaging Tape

Solvent-based packaging tape is the strongest and best choice. This tape is fantastic as it sticks well to different surfaces. It is working well in hot or freezing situations. While it is expensive, it give secure seal that will not peel.

- Strong Adhesion And Durability

To ensure your parcels stay secure, you need tape that is strong and sustainable. Solvent and hot-melt tapes are famous for their deep grip on cardboard. Durability means the tape will not snap under pressure. Thicker tapes are handle rough shipping goods.

- Performance In Extreme Conditions

Extreme conditions require special tape. It works well in cold warehouses. Unlike standard tapes, it keeps its grip when the surface is dusty. Using the right tape ensures your boxes stay sealed in the storage location.

Paper Packaging Tape

Paper packaging tape is a green-friendly alternative to plastic. It is usually made from kraft paper. It can be recycled directly along with your cardboard boxes.

These are the two main kinds. So, self-adhesive paper tape. Both work as standard tape or water-activated tape. Both give a masterful look and a secure seal for your parcels.

Water-Activated And Pressure-Sensitive Options

- Water-Activated Tape (WAT)

These tape uses good starch-infused glue. You must wet it with water to make it sticky. It creates a permanent bond with the cardboard.

- Pressure-Sensitive Tape

It is sticky right away. You just press it down firmly onto the surface. It is fast and easy to use with a hand dispenser, making it great for most everyday parcels.

- Use In Eco-Friendly Packaging

eco-friendly packaging is used to save products and also not harm the Earth. It uses plant-based materials. It helps to support a cleaner, greener future.

Masking Tape

The masking tape is made from thin paper. It does not leave marks behind. Use it for painting to get straight lines. It is also great for temporary labels on boxes.

- Temporary Sealing And Labelling Purposes

Temporary sealing and labelling are used to hold items safely for a short time. They help identify products clearly. Labels give basic information. Seals are easy to remove. This makes packing, checking, and handling faster and more efficient.

- Easy Removal Features

Easy removal features allow users to open packaging quickly. No tools are needed. They reduce effort and mess. This makes products safer to use and more convenient for daily handling.

Filament (Strapping) Tape

Tape.webp)

Filament strapping tape is very strong. It is used to bundle and secure heavy items. The fibreglass strands add strength. It helps keep boxes tight during storage and transport.

- Reinforced Fibres For Added Strength

Reinforced tapes contain strong glass fibres. These hidden strands make the tape impossible to tear by hand. It provides extra security for heavy boxes. This prevents the parcel from bursting open.

- Use In Bundling And Heavy Packaging

It is used for bundling and heavy packaging. It holds items together firmly. The strong tape prevents movement.

Double-Sided Tape

This tape is sticky on two sides. It is used to join both surfaces invisibly. Simply stick 1 side down, peel off the paper liner.

- Discreet Bonding For Packaging And Inserts

Discreet bonding is used to fix packaging and inserts neatly. It keeps parts in place without showing. The bond is clean and tidy. This improves appearance and protects the contents.

- Application In Presentation-Focused Packaging

It is used in presentation-focused packaging. It keeps items neat and well placed. The finish looks clean and smart.

Adhesive Types Used In Packaging Tapes

Acrylic is long-lasting. Rubber gives a quick stick. Silicone handles heat well. Each type suits different packaging needs and working conditions.

Acrylic Adhesives

Acrylic adhesives are very strong. They resist ageing sunlight. They work well on many surfaces in packaging.

Rubber-Based Adhesives

Rubber-based adhesives stick quickly with a durable grip. They work good on rough places. They are common in packaging tapes.

Solvent Adhesives

Solvent adhesives use chemicals to stick surfaces perfectly. They bond strongly and fast. They work perfectly for heavy-duty packaging.

How Adhesive Choice Affects Performance

Adhesive affects the strength and sustainability. The right type keeps packaging secure. It works wow in different conditions.

Materials Used In Packaging Tape Manufacturing

Packaging tape is designed from plastic or paper. It uses adhesives reinforcing fibres for more strength.

- Polypropylene (PP)

- PVC

- Kraft paper

- Fibreglass reinforcement

- Compatibility with custom cardboard and corrugated boxes

Packaging Tape Performance Considerations

Packaging tape depends on stickiness, durability, and surface type. Select the right tape keeps packages secure. Packaging tape makes storage safe and reliable.

- Load-Bearing Capability

Load-bearing capability shows how much weight a tape can bear. Stronger tape keeps heavy products secure during handling.

- Shelf Life And Storage Conditions

Most tapes last 2 years. Storing rolls in a cooler and a dry room temperature of 15 to 25° C. So, keep them out of direct sunlight.

- Temperature And Humidity Resistance

Temperature and humidity resistance show how tape works well in heat and cold. This tape sticks in different conditions.

Sustainable & Eco-Friendly Packaging Tape Options

Durable and green-friendly is easy to recycle. Both are the best options for items.

- Recyclable and biodegradable tapes

- Plastic-free paper tapes

- Water-activated tapes and reduced waste

- UK sustainability and recycling expectations

Common Applications of Packaging Tapes in the UK

Packaging tapes are used for sealing boxes perfectly. It keeps packages secure during delivery in the UK.

- E-Commerce Shipping

E-commerce shipping uses packaging tape to seal boxes well. It keeps product save and ready for delivery to users.

- Retail Packaging

Retail packaging uses tape to secure products neatly. It keeps items safe, organised, and looking attractive on shelves for customers.

- Warehouse Storage

Warehouse storage uses tape to bundle and label boxes. It keeps goods organised, secure, and easy to move or find.

- Industrial And Logistics Use

Industrial and logistics use tape to secure heavy packages. It helps to shift items securely. It keeps boxes stronger.

How to Choose the Right Packaging Tape

Let's choose packaging tape. The right tape keeps packages safe.

Matching Tape Type To Box Weight And Material

Matching tape type to the box weight or material. Strongest tape for heavy boxes, lighter tape for light boxes.

Cost-Efficiency Vs Performance Needs

Low cost and performance when selecting tape. Cheaper tape saves money. The strongest tape keeps packages more secure.

Compliance With Uk Packaging Standards

Packaging must follow UK standards to be safe and reliable. Tape and materials should meet rules for strength, safety, and environmental care. Proper compliance protects goods and supports legal requirements.

Conclusion

Packaging tapes are best for keeping boxes and items safe. There are many types of tapes for many uses. Acrylic tape lasts long and handles sunlight perfectly. Rubber-based tape sticks fast and works on rough surfaces. Solvent-based tape is stronger and good for heavy-duty work. Tapes are designed from materials such as paper and film.

Sometimes with extra fibres for strength. Selecting the right tape depends on box weight and the conditions it faces as humidity. The Custom Boxes give green-friendly options that help reduce waste and save the environment. Using the right tape makes packaging neat. Safe and masterful, whether for e-commerce. Also, retail, warehouses, or industrial shipping. Using tape ensures parcels do not open due to damage.

Frequently Asked Questions

What kind of tape for packaging?

Use water-activated paper tape for the best eco-friendly strength and security. Use clear plastic tape for a quick, easy, and waterproof everyday seal.

What is another name for packaging tape?

Another name for packaging tape is parcel tape. It is also called carton sealing tape. It is used to close and secure boxes safely.

What are the three main types of adhesives?

The three main types of adhesives are acrylic, rubber, and solvent-based. Acrylic lasts long and handles sunlight well. Rubber sticks quickly, and the solvent is strong for heavy-duty use.

What is the difference between strapping tape and packing tape?

Strapping tape is very strong and reinforced for heavy packages. Packing tape is thinner and used for sealing normal boxes. Strapping tape holds weight, while packing tape secures and protects.

What kind of tape lasts the longest?

Acrylic tape lasts the longest because it resists sunlight and temperature changes. It stays sticky for up to ten years, making it ideal for long-term storage.

What is PVC tape?

PVC tape is made from plastic called polyvinyl chloride. It is strong, durable, and water-resistant. It is used for sealing, insulating, and protecting packages.