The Ultimate Custom Cardboard Boxes Size Guide

Discover the perfect fit, your go-to guide for choosing customised cardboard packaging boxes with clarity and confidence. Read on to craft perfectly fit boxes for your amazing products.

The size of the cardboard box you choose is more important than you might think. It influences shipping. The Custom Boxes had to repackage the goods into boxes that are too small, and the boxes may contain too much or too little padding or have damaged products.

We understand how small shifts in dimensions can ripple through your operation, logistics and brand perception. We'll guide you through every aspect of cardboard box sizes UK in this blog, including standard and custom options, so you can confidently choose your packaging.

Understanding Cardboard Box Dimensions

What Do Dimensions Mean?

- Length of the box is typically its longest side.

- Width is the side perpendicular to the length.

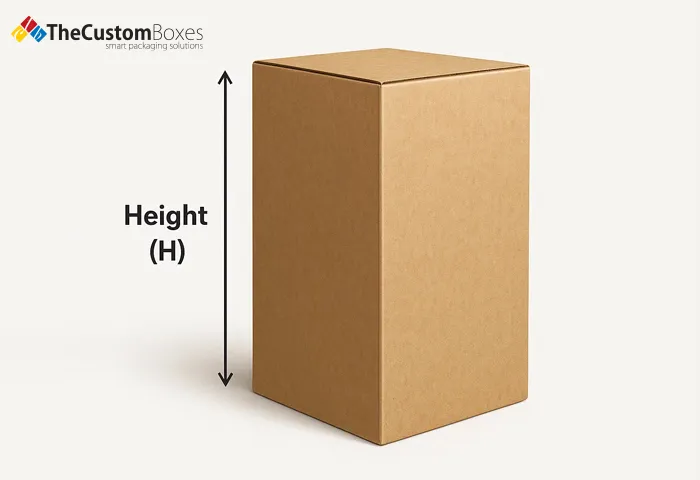

- Height (or depth) is the vertical dimension when the box rests on its base.

Internal Vs External Dimensions: How To Measure Correctly

It is crucial to know whether dimensions refer to internal (usable) space or external size. For shipping rate calculations, you often need the external size, but for fitting the product, you rely on internal dimensions. Use a steel rule or tape measure, measure inside the walls for internal and outside for external.

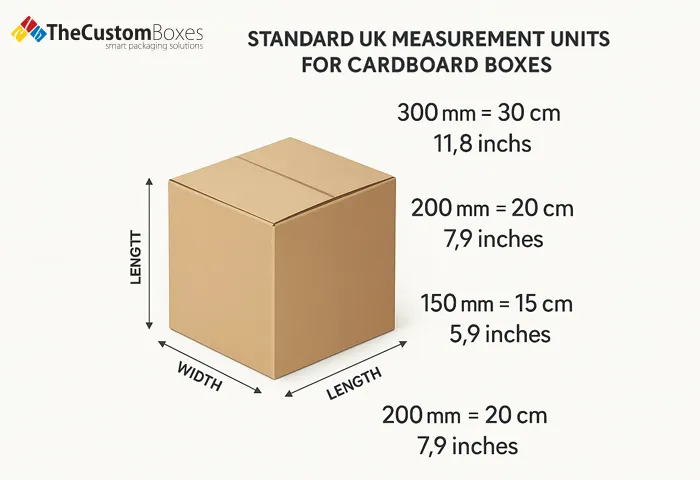

Standard UK Measurement Units

In the UK, you will commonly find three measurement units:

-

Mm (millimetres) — very precise, often used in manufacturing.

-

Cm (centimetres) — convenient for everyday use.

-

Inches — still used in international shipping or older specs.

Being able to convert between mm, cm, and inches helps when comparing with global specifications.

Standard Cardboard Box Sizes in the UK

When choosing box sizes, you’ll notice many standard options rather than wholly bespoke shapes. At The Custom Boxes, we offer custom solutions in addition to standard cardboard box sizes.

Standard UK Box Sizes

The types of packaging used in the UK are numerous, but some types of boxes are the ones that most companies rely on daily. These conventional cardboard box sizes are the ones that are intended to fit all the postal deliveries, storage and display in shops.

- The most popular ones are A4-sized cardboard boxes. They are approximately 310 by 220 by 70 millimetres (approximately 12.2 by 8.7 by 2.8 inches) and make great storage accommodations for papers, documents, catalogues, and other slender items.

- The A3-sized cardboard box is the ideal box when dealing with slightly bigger products. It has the dimensions of about 420 -310 -100 millimetres (16.5-12.2-4 inches) and offers additional space to place posters, prints or even small electronic devices.

- The postal box can be trusted when it comes to the delivery of small parcels via the post. These boxes are sized at approximately 250 x 165 x 165 millimetres (approximately 9.8 x 6.5 x 6.5 inches) and are ideal to store cosmetics, accessories, a gift or even a mail-order.

- When you have something to pack that has to have the same amount of space on every side, then cube boxes are a great choice. They typically have dimensions of approximately 300 x 300 x 300 millimetres (approximately 11.8 x 11.8 x 11.8 inches) and will be useful with the toys, hampers or larger volume bulk packaging that can be stacked together.

Size Discussions

- A4-size cardboard boxes: Ideal for documents, folders or flat items.

- A3 size cardboard box: Suited for files, small flat electronics or large prints.

- Postal boxes / small parcel: Optimised for standard courier size tiers, good for ecommerce items.

- Cube boxes (medium): Versatile for product sets, multiple small items or space-efficient shipping.

- Large-letter / large parcel box: Meets many UK courier thresholds before “oversize” surcharges apply.

Royal Mail & Courier Guidelines for Parcel Size Limits

The carriers like Royal Mail and couriers have size and weight restrictions, after which they charge special rates in the UK.

Comparison Chart: Standard vs Custom Box Cost and Efficiency

|

Box type |

Cost per unit |

Efficiency(void space) |

Branding & fit |

|

Standard-size box |

Lower(mass-produced) |

Moderate |

Generic branding |

|

Custom size box |

Higher(tailored) |

High(minimal void) |

Strong branding fit |

Stated briefly, generic boxes are economical in many applications; bespoke size is a winner where product fit, branding or shipping efficiency is of significant concern.

Custom Box Sizing for Different Products

You have to decide on how to make the box big enough to fit a particular product since the size of the shelves is not always adequate.

Cosmetic, Electronics, And Clothing Online Packaging

- Clothes: Thinner boxes are shipped at reduced costs, and padding costs are also reduced.

- Cosmetics: Smaller box size often, with presentation focus and printing.

Using the right size reduces wasted space, material cost and shipping chargeable weight.

Retail Display Boxes: How To Size For Shelf Visibility And Presentation

Shelf presence is important in retail. Custom sizing guarantees that boxes fit store racks precisely. To match packaging style with marketing design, brands use tools such as Custom Boxes With Logo.

Food & Beverage Packaging: Accounting for Insulation and Hygiene

Box size must allow for insulation, rigid supports and safe stacking. Even though you might use a standard size, you need to leave space for inserts, padding or chilled elements. Choosing cardboard boxes large size for catering makes it easier to safely handle larger quantities.

Products that are heavy and delicate

It is possible to load delicate or heavy items into a heavier type of box (double-wall corrugated, for example). Internal size is impacted by this: the thicker the material, the less space that can be used. This is because it is always calculated on the inner (internal) size when material is taken into consideration.

How to Choose the Right Box Size for Your Product

Product stepwise process measurement.

- Measuring the length, width and height of a product.

- Insert a little clearance (5-10mm) in all directions.

- Take a box whose internal size is equal to or a little larger than the space.

For examples of how to choose properly, visit our page on Standard Mailer Boxes Sizes and Dimensions if you're not sure.

Material thickness impact on internal space

If you select a thicker material (for strength), then the internal volume shrinks. For example, a box that externally measures 310 × 220 mm may only have 300 × 210 mm internal space if the walls are 5 mm thick on each side.

Design Tools for Custom Measurements

Numerous online resources are available to assist you in designing the appropriate structure if you want to learn how to make a custom size cardboard box. Before placing an order with your cardboard box maker, you can create digital samples, preview layouts, and enter your dimensions.

Box Style and Size Correlation

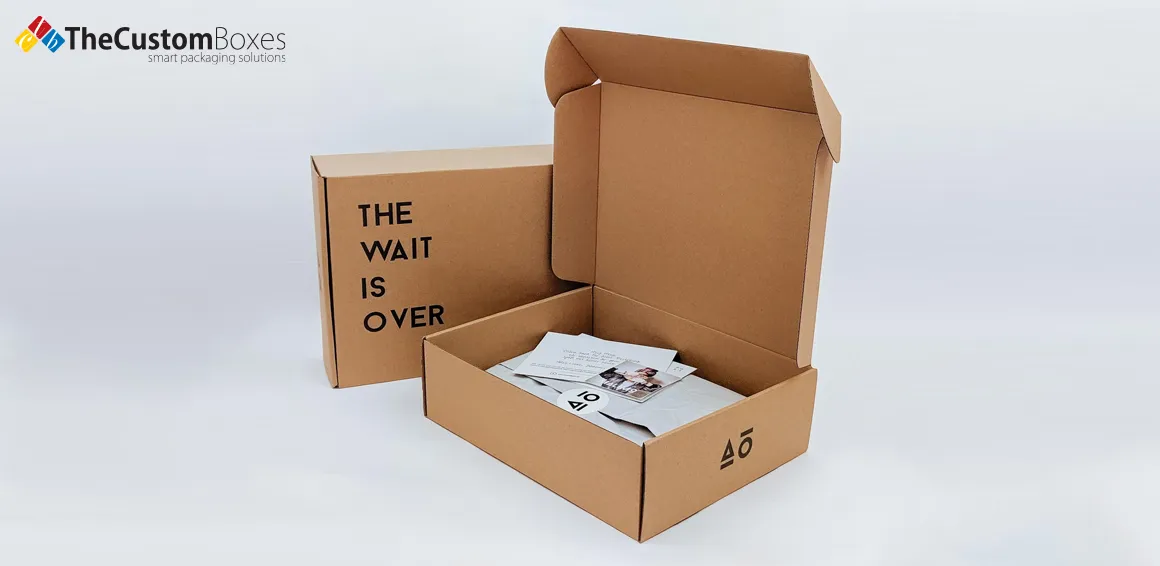

Mailer

Slim, self-locking boxes designed for direct shipping of flat or light items. Ideal when you want cardboard box small size solutions.

Tuck End

A classic retail style box with tuck-flaps. Works well when presentation counts and sizes are moderate.

Corrugated

Made from fluted cardboard, excellent strength for shipping and heavy items. Typical corrugated cardboard box sizes cater to heavier loads.

Die Cut

Highly customised shapes and designs, often for premium retail display or specialised packaging. Size must be tailored to fit the product and brand.

Choosing Box Shapes For Branding And Storage Efficiency

The choice of a box shape and size has an impact on stacking, storage use and appearance. An example to illustrate this is that a cube box can be stacked neatly in a warehouse, but a tall and narrow box can be placed better on a shelf.

Alignment of shape and product, and logistics assists in the optimisation of operations. To learn about shape variation in retail packaging, check out our comprehensive guide on shoe box sizes and dimensions.

Eco-Friendly Materials And Recycling Standards In The UK

Recycling standards in the UK imply that boxes with cards should contain recycling symbols and should reuse or use recycled materials wherever possible. Choosing the correct size reduces waste, void fill and excessive material, helping sustainability. The industry is increasingly favouring boxes that are easy to recycle after use.

Tools & Templates for Box Size Calculation

Online box dimension calculators and AR packaging tools

Several websites let you input length, width, height, and they calculate optimal box size, volume and even cost. These tools help you explore “how to make a custom-sized cardboard box” without guesswork.

Printable measurement templates and design software

You can also download PDF templates to trace your own box shape, or use design software like Adobe Illustrator with box-style templates. These assist when working with a service such as a cardboard box maker that can produce your custom sizes with precision. Check out our comprehensive How To Make Custom Boxes tutorial for inspiration and education, where we walk you through the entire design and delivery process.

Conclusion

In reviewing this guide, you now understand the key elements: how to measure length, width and height; how standard sizes such as A4 size cardboard boxes and A1 size cardboard boxes fit many needs; and when it makes sense to go with custom cardboard boxes UK to optimise fit, shipping and branding. To ensure the ideal packaging each and every time, we at The Custom Boxes UK encourage you to use our custom box size calculator or get a quote from our UK packaging specialists.

FAQs:

1: What are the standard sizes of cardboard boxes?

Standard UK box sizes include formats like A4, A3, small parcels and large letters.

2: How do I calculate what size box I need?

Measure your product, add clearance and padding, then pick a box with an internal size matching that space.

3: What size is a TVL 12 box?

The “TVL 12” designation varies by manufacturer—check their chart or ask for actual dimensions.

4: What is the order of box dimensions?

Length × Width × Height is the typical order in UK packaging specs.

5: What is the size L * W * H?

It refers to Length times Width times Height—the three dimensions of the box.

6: Which goes first, length or width?

Length goes first, and then the width.

7: What does 10 × 12 mean?

These usually length and width dimensions are 10 x 12.

8: How to measure the width of a box?

Measure the shorter horizontal side of the box when it is on its base.

9: What are common box dimension mistakes?

Mistakes include measuring external size when internal is needed, ignoring wall thickness or mixing up L/W/H order.

10: What order do dimensions go in the UK?

Typically, Length × Width × Height in that order for both internal and external specs.