Difference Between Offset and Digital Printing For Packaging

Discover the difference between offset and digital printing for packaging. Learn which method suits your brand’s needs. We break down each process to give you the best package; this is in terms of cost, speed, etc.

Printing does not just involve getting ink on paper, but it is the craft of bringing ideas to life. The way you do it can alter the appearance, feel, and durability of your design. Offset printing has clarity and deep colour, making it an ideal choice for a premium feel. Speed, flexibility, and bright results that work with contemporary demands are solutions of digital printing. That difference makes you select the style that most suits your brand and your budget.

The global packaging printing market was valued at over 350 billion dollars in 2023, and it is growing fast. Experts say it may grow by more than 9 per cent every year. This shows how important choosing the best printing method for packaging can be for a business. Many brands pick between two main methods: offset and digital. Each works in a different way. All of them are associated with their own rates, pace, and quality. The option can interfere with sales, marketing, and customer perception of the product.

The Custom Boxes offers both offset printing for bulk orders and digital printing for small businesses. With the right choice, brands can save money and improve their look. In this blog, we will explore these two printing types in detail.

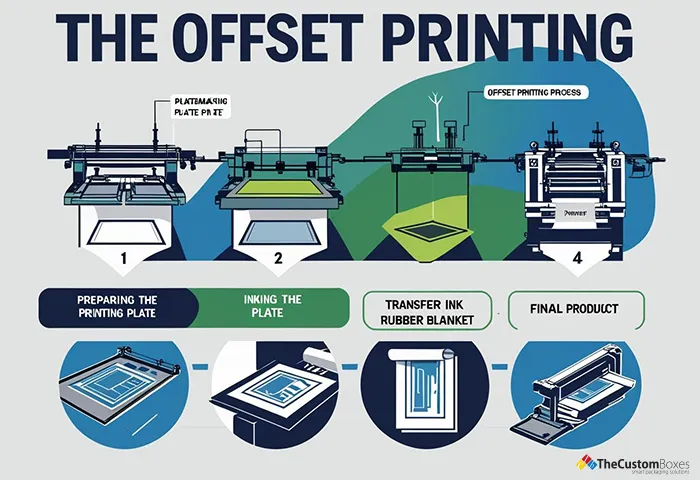

What is Offset Printing?

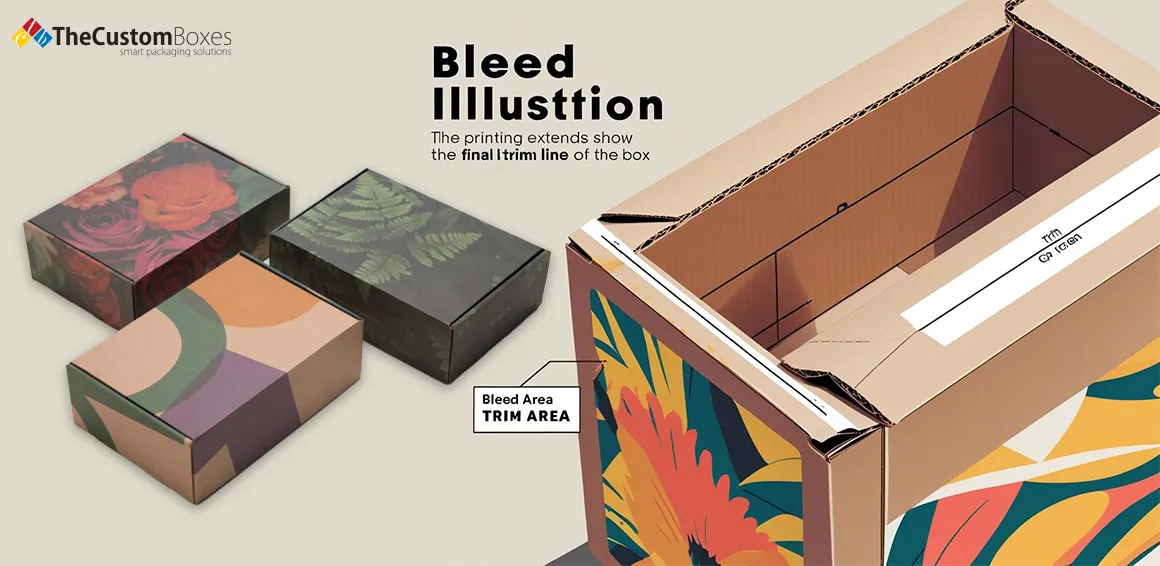

The image is first burnt into metal plates. These plates roll ink onto a rubber blanket. The blanket then presses the image onto the packaging material. This method works well for large runs. Once the plates are made, printing many copies is fast and cheap per piece. This makes it ideal for brands that need thousands of the same box or label.

The Custom Boxes often use this for making high-volume customised boxes. This process delivers sharp images and rich, even colours. Offset printers can run thousands of sheets in a short time. This keeps production moving and costs low when orders are big. However, setting up offset printing takes time. Making plates and adjusting the press can take hours. This is why small runs cost more. It is not flexible for last-minute design changes.

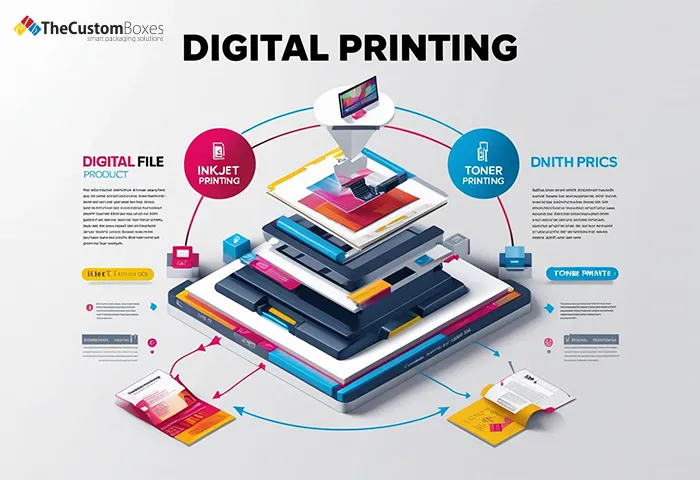

What is Digital Printing?

Digital printing works more like a home printer, but on a larger scale. The design is sent directly from the computer to the printer. No plates are needed. Ink or toner goes straight onto the packaging material. This makes it perfect for short runs or special designs. A digital printing company can print just one box if needed. This is great for testing new products or running seasonal promotions.

The Custom Boxes uses digital printing to make custom boxes with logo in small batches. It works well for custom bakery boxes, custom donut boxes, or other designs that change often. Digital printing also supports variable data printing. This means each box can have a different name, number, or image. This is ideal for personalised packaging. While the cost per piece is higher than offset for big runs, it saves money when quantities are small.

Offset Printing vs Digital Printing

Choosing between these two is a printing methods comparison that depends on volume, budget, and design needs. Offset printing shines for bulk jobs. Once plates are ready, the cost per unit drops sharply. For example, printing 5,000 boxes with offset can be much cheaper than digital. Some machines print more than 15,000 sheets per hour. This is why big brands choose offset printing for bulk orders.

Digital printing wins for speed to market. Since there is no plate setup, jobs can start in minutes. This can be the best printing method for packaging when launching a small product quickly. Quality differences are small today. Offset offers slightly sharper images and better colour matching, which matters for strict branding. Digital offers vivid colour and fine detail too, but may vary slightly between runs.

Our company helps clients decide. Some projects even mix both methods: digital for short tests and offset for mass production. This way, brands enjoy both speed and cost savings.

Benefits Of Digital Printing / Offset Printing

-

Offset printing benefits:

It delivers consistent quality over long runs. Colours stay exact, and images stay sharp. This is why many luxury brands pick offset for chocolate boxes or high-end macaron boxes. It is also very cost-effective when printing thousands of items.

-

Digital printing benefits:

It offers flexibility and speed. The brands are easy to place new designs, and that is why it is excellent when printing boxes that advertise time-specific offers or seasonal designs. This does not have any additional setup cost, and this enables small businesses to compete.

Both of the methods allow quality findings. The choice often depends on run size, budget, and how often designs change. Brands can work with a trusted offset printing company or digital printing company to match the right method to the job.

When To Use Digital Printing / Offset Printing

Use digital printing for small batches or products with many design changes. This is ideal for digital printing for small businesses testing new packaging styles. It is also great for personalised campaigns. Use offset printing for large, steady orders. It becomes cheaper than digital at a certain point. This point is often around 2,000 pieces, but it depends on size and design. Big brands often choose offset when they need the same box for months or years.

We guide clients on choosing the right method for their goals. We may start a new design with digital, then switch to offset printing when sales grow. This keeps quality high and costs low.

How Printing Affects Branding

The type of printing changes how people see your product. High-quality printing can make packaging feel more premium. This builds trust and increases the chance of repeat sales. Brands that invest in quality printing often see better shelf appeal.

Whether you choose offset or digital, the final look will influence how customers remember your brand. Crisp colours, clear text, and smooth finishes all send a strong signal about product value.

Cost Trends in Printing

Over the last decade, printing costs have changed. Digital printing has become cheaper as technology has improved. Offset still offers the lowest cost per unit for large runs. But in short runs, digital has closed the gap.

Knowing these trends helps businesses plan ahead. If you expect low volumes, digital can be the smarter start. If sales rise, offset can take over to save money long term.

Printing and Seasonal Packaging

Printing choices also affect seasonal marketing. Digital printing allows fast changes for holidays or events. This means custom bakery boxes can feature new designs for Christmas, then switch to Valentine’s Day without delay.

Offset works well for steady seasonal lines. If you sell the same holiday product every year, offset plates can be reused, saving setup time and cost.

Printing and Brand Identity

Your printing choice can change how people see your brand. Offset printing gives a sharp and rich look that feels premium. Digital printing can make bright, eye-catching designs that work for fun or modern brands. The colours and details you choose show your style. Offset works well for brands that want a timeless, classic image. Digital is great for brands that like to change designs often.

Speed in Meeting Deadlines

Sometimes you need packaging fast. Digital printing is great when time is short because it needs no plates. Offset printing takes longer to set up but works quickly once it starts printing large orders. If you have a launch coming soon, digital printing can save the day. It allows last-minute changes without extra cost. Offset, on the other hand, works best when your design is final. This speed difference can make or break a project deadline. Both methods can deliver on time if planned well.

Mixing Both Printing Styles

Some brands use both printing methods for the best results. They print the main design with offset for high quality. Then they add custom details with digital printing for a personal touch. This mix can lower costs while keeping designs fresh. Offset handles bulk printing of standard elements. Digital takes care of names, dates, or limited-edition graphics. Brands love this because it gives them flexibility. You can keep your base design the same but change details anytime. Mixing both styles gives you quality and creativity in one package.

Environmental Impact

Printing affects the environment. Offset printing uses plates and more chemicals in the setup process. It also needs more paper for test runs. But it can be more efficient for large runs because less energy is used per piece.

Digital printing uses less setup waste. It does not need plates or much test paper. Choosing the right method also helps reduce carbon footprint.

Conclusion

Offset printing and digital printing each have clear strengths. Offset is the choice for bulk orders, long runs, and exact colour matching. By knowing these printing technology differences, brands can save money and keep their packaging sharp. This can help products stand out in a busy market. The Custom Boxes works to match each job with the right process. This keeps brands looking their best while controlling costs. You should buy the boxes from our company to enhance your brand or business. With the right printing, your packaging can become a silent salesperson.

FAQs

What does 'offset' mean when printing?

Offset printing is such a printing technique where the inked image is moved to a plate, which after being passed over to a rubber blanket is moved to the surface being printed. It yields high-resolution prints and is best to use when doing large runs.

How can you tell if a print is offset or digital?

Offset prints tend to be smooth and uniform in colour and do not have any dots in their appearance when magnified. Tiny dot patterns, toner shine, and tiny colour banding of gradients on digital prints may be observed.

Which printing method is more cost-effective?

Offset printing is relatively cheaper when the amount at hand is high since the cost per unit reduces considerably after the initial setup. On small quantities, digital printing is less expensive because no plates or setupcosts are incurred.

Can I use digital printing for packaging?

Is digital printing good on packaging? Yes, when you have a need for custom designs, a short run or variable data. It is quick and versatile and can deal with complicated artwork with comfort.

Is digital printing more eco-friendly than offset?

Digital printing may have good environmental credentials in short runs due to low waste and no plates or chemicals. Offset may be more effective in resource consumption, however, in large runs

.webp)