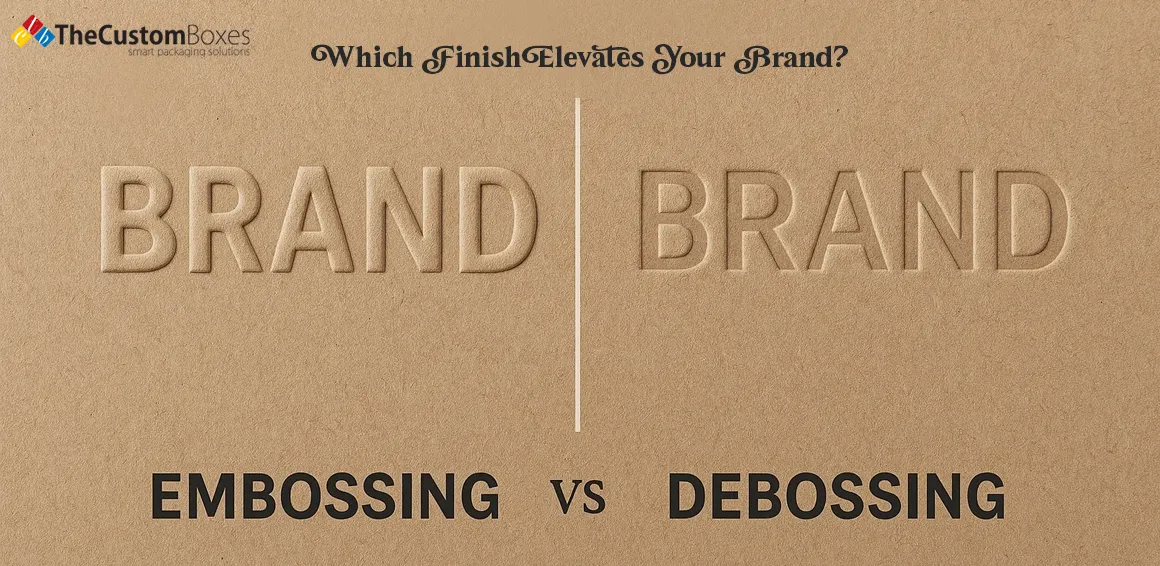

Embossing Vs Debossing: Which Finish Elevates Your Brand

Explore how embossing and debossing can increase your company. It is also used heavily on leather goods like diaries and menus for a lasting, high-end mark. They both make a product feel more valuable. Debossing may be combined with foil for extra detail.

Are you searching for a print finish that makes your brand wow? Embossing and debossing are the most effective ways to incorporate style. Also, add texture to your packaging or print. Embossing increases the design. It works well for logos and key details you want to highlight. Debossing is a process of pressing the design and text into the surface.

The Custom Boxes designs embossing and debossing. Both finishes include a touch of the best quality. Choose debossing for understated charm. We make your brand look high-quality. Embossing lifts the design. It creates a raised, 3D effect. This looks bold and catches the light. Both techniques add texture and value to cards or packaging. In this amazing article, we will discuss embossing vs debossing. Its finish promotes your brand.

Importance Of finishes In Brand Perception

Finishes are the silent ambassadors of your brand. They are the final layer added to print items. The right finish instantly signals quality and care. It shows you do not cut corners. Finishes create a tactile experience. People process touch quickly. A nice feel builds trust.

- A smooth, soft finish suggests sophistication.

- A bold, raised finish suggests confidence.

Finishes make your materials memorable. They help you stand out from plain print. This boost in perceived value is vital for winning customers.

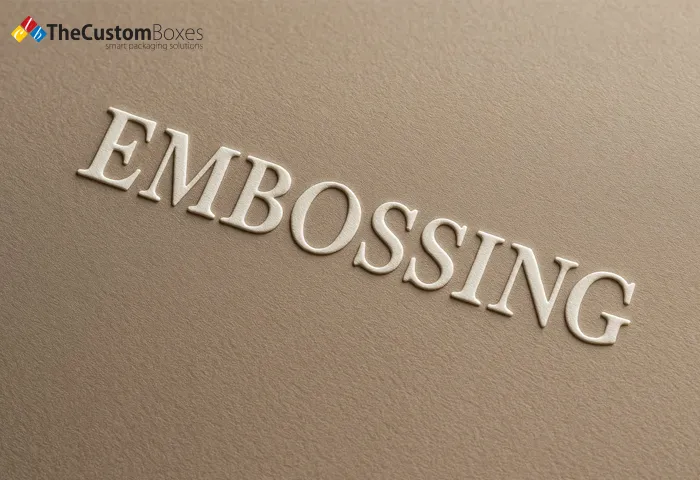

What Is Embossing?

Embossing is a printing method that creates a design on the surface. Its design lifts the you may see or feel. A metal die is used to press the shape into the material, making the area fantastic. Embossing is most used on logos, names, and patterns. It offers packaging and brand cards with a good look.

Process

Embossing creates a raised design on materials like paper, metal, plastic, and glass. The image stands proudly on the surface. This adds a tactile, three-dimensional quality. The process uses two metal dies. One is raised male, and the other is recessed female.

The material is clamped between these dies. Great pressure and sometimes heat are applied. This forces the material to take the dies' shape.

Common Materials

Embossing and debossing work on similar materials. Paper and card are the most common because they shape easily. Leather is also used for luxury items. Some plastics and packaging boards can take both finishes well. Embossing raises the design. So it is often used on business cards, gift boxes.

Benefits For Brand Image

- Embossing and debossing help a brand look more premium.

- They add texture that people can feel and remember.

- The design stands out without using bright colours.

- They make packaging feel special and well-made.

Customers often link this feeling with trust. These finishes also improve recognition.

Expert Insight: When Embossing Is Most Effective

Embossing is a great selection when you want a clear, bold finish. It helps key details look important and memorable. The raised texture catches attention. It adds a sense of quality without using extra colour or ink. Use embossing when you want impact, clarity, and a strong first impression.

What Is Debossing?

Debossing is a printing technique that presses a design down into the surface. It creates an indented effect you may see and feel. A metal die is used to push the shapes into the material. It is used on logos, brand names, or patterns. Also, offers packaging, business cards, and book covers with a fantastic look. The smooth dip includes texture without being too bold.

Process

A deboss is a recessed design pressed into a material. It leaves an impression below the surface level. The method is popular for branding and decorative finishing. The process uses two main elements.

A metal die is heated and crafted with the design. This die is pressed firmly onto the substrate material. Heat and pressure force the material downwards. Unlike embossing, the material is pushed in, not pushed up. It results in a clean and elegant tactile effect.

Use Cases In Print And Packaging

Both finishes have great uses. Embossing is perfect for eye-catching materials. Use it on luxury folding boxes. It highlights product names or logos for high visibility. It is excellent for formal certificates to show authority. Debossing is often used for a refined feel.

How Debossing Impacts Visual And Tactile Appeal

Debossing creates a deeply sophisticated visual appeal. Light hits the edges and casts a subtle shadow. This effect adds an immediate sense of depth and quality. It is favoured for a quiet, understated elegance. The technique strongly enhances the tactile appeal.

Authoritative Example: Premium Brands Using Debossing

Premium brands frequently utilise debossing for a subtle, classic finish. Luxury leather goods brands often use it. Their wallets, handbags, and travel tags feature debossed logos. This technique is also common on high-end stationery. Perfume and cosmetic boxes also carry debossed branding.

Key Differences Between Embossing And Debossing

Embossing creates the design. The image sticks up from the surface. It uses two plates or dies. This effect is usually bolder. Debossing sinks the design. It often uses only one die. This effect looks more subtle and elegant.

-

Visual Vs Tactile Effects

Visual effects relate purely to sight. These add elements like colour and shape. A striking colour or bold logo impacts visual attraction. Visuals are instantly perceived from a distance. They capture initial attention and establish brand recognition.

- Cost And Production Considerations

Production starts with a custom metal die. This is a big, one-time fee. It is the most costly item upfront. Embossing often costs more. This is because it needs two matching metal plates.

Debossing is usually cheaper. It requires only one plate. Ordering large numbers lowers the cost per item. Detailed designs and thicker materials increase the total price.

- Best Scenarios For Each Technique

Embossing is best for drawing attention. Use it for logos or titles that must stand out. It creates a very dramatic look. Think of certificate seals or book covers. Debossing is best for a premium feel. Use it for subtle branding and elegance. It works well on leather goods or luxury packaging. It gives a sophisticated, lasting touch.

- Trust-Building Tips: Avoiding Common Mistakes

Trust grows from smart decisions. Do not overuse design effects. Simple looks more professional. Choose strong materials. Keep colours and logos consistent. Inconsistency causes doubt. Review all text carefully. Fast work creates mistakes. Always test samples first. Clear planning and clean execution help people trust your brand.

How To Choose The Right Finish For Your Brand

Your finish must match your brand identity. A gloss finish is very bold and vibrant. It suggests professionalism and high quality. Also consider the product use. Will people touch it often? Use durable finishes like laminates. For luxury items, try debossing or foil stamping. These effects feel premium.

- Factors To Consider

- Begin with your target audience.

- Think about their age, style, and preferences.

- Different groups like different designs.

- Next, look at the product type.

- Boxes, labels, and packaging need different finishes.

- Some need durability, others a premium feel.

- Finally, consider your budget.

Expert Recommendations And Case Studies

Experts recommend keeping designs clear and simple. Too many effects can confuse people. Use quality materials to show value. Case studies show top brands use subtle finishes for a premium feel. Successful examples prove that planning matters.

Enhancing Brand Perception Through Thoughtful Design Choices

Thoughtful design improves how users see your company. High-quality materials signal excellence. Use of your logo builds trust and is memorable. Selecting the right finish is important. A matte finish is best. A gloss finish feels modern.

Conclusion

Embossing and debossing both show a brand’s look and feel. Embossing lifts the design on the surface. It feels bold and very noticeable. Debossing presses the art into the surface, or feels luxurious. The right choice depends on your brand style. It suits bold, decorative designs perfectly. Debossing fits premium, minimal designs.

They make products feel valuable and memorable. Think about your product, budget, and message. Testing samples helps you choose. Such a finish makes your company look trusted and more high-quality. It is an ordinary way to add style and a high-quality feel to your printed products.

Choosing the right finish builds trust and authority. Clear, consistent designs show care and quality. Subtle, well-planned effects feel premium. Testing samples avoids mistakes. So, contact The Custom Boxes and improve the aesthetic appearance of your customise packaging boxes.

Frequently Asked Question:

What Are The Advantages Of Embossing And Debossing?

These techniques give the design a better feel. They make items more memorable and boost their value. Embossing is bold and great. Debossing is durable.

Is Embossing Considered A Luxury Finish?

Yes, embossing is a luxury finish. It offers a design with a raised, 3D effect that feels very high-quality. This detail increases a brand's great perception.

What Are The Disadvantages Of Embossing And Debossing?

A drawback is the high upfront price of the custom metal die. This specialist process is also slower than normal printing. Embossing leaves a slight impression on the paper's back side.

Is Debossing More Expensive?

Debossing can cost more than simple printing. It needs special tools and time to press designs. The price increases with complex shapes.

What Is The Most Eco-Friendly Printing Method?

Digital printing is often the most green-friendly. It also uses less water, energy, and ink waste. It is best for low-impact designs.

Which Is Better, an Embosser Or a Stamp?

An embosser creates raised, stable designs. A stamp uses ink and is temporary. Choose an embosser for a good look and a stamp for easy use.

Which Embosser Orientation Is Best?

The best embosser orientation is mostly vertical. It keeps logos clean and easy to read. Choose the orientation that matches your design and items shape.

Can You Emboss And Deboss Together?

Yes, you may emboss and deboss together. It includes depth to your design. Use it carefully to keep a professional look.

What Is Golden Embossing?

Golden embossing raises the design and adds the best gold finish. It creates a luxurious look. It is often used on premium packaging.

, and How Is It Used in Printing.webp)