What Is MOQ In Packaging? | The Custom Boxes

MOQ in packaging means the tiny number of products you should order at once. It helps suppliers keep prices low. MOQs can differ by product and material. Knowing the MOQ helps you simplify, budget, and avoid unexpected extra amounts.

Do you struggle with packaging orders? MOQ is very helpful for the smallest number of units your packaging supplier will permit you to buy at once. Our suppliers establish an MOQ due to their fixed item costs. These costs cover things like setting up machinery and preparing printing components. The Custom Boxes designs the MOQ in the best Packaging. Our manufacturing products are efficient and profitable for them.

A higher MOQ usually results in a lower price per individual unit. MOQ helps you manage your spending and plan your necessary stock levels effectively. In this amazing article, we are going to discuss what MOQ is, which stands for Minimum Order Quantity.

What MOQ means In The Packaging Industry

This is a common term in the packaging industry. The smallest number of packaging units. Supplier agrees to sell to you in a single transaction. You must purchase this number or more. Suppliers set this minimum to make sure each production run is profitable.

Why MOQs Matter For UK Businesses Ordering Boxes, Bags, Labels, Or Printed Packaging

MOQs are crucial for UK businesses buying any custom packaging. It matters for a few main reasons. Firstly, it affects your price. Suppliers spread their fixed setup costs, like printing plates, over the whole order. A larger MOQ often means a lower cost per box or bag. Secondly, it impacts your cash flow. A high MOQ means more money is tied up in packaging stock. Thirdly, it helps you plan your inventory.

Understanding MOQ (Minimum Order Quantity)

Understanding MOQ is important when buying packaging. MOQ means the smallest number of items you must order from a supplier. Suppliers set MOQs to cover their costs and keep production running smoothly. A high MOQ can make each item cheaper, but you have to buy more at once.

MOQ stands for Minimum Order Quantity. It is the smallest batch size a UK supplier will produce. This minimum ensures the order is profitable for the factory. High volumes keep the cost per item low.

Why Packaging Manufacturers Set MOQs

Packaging designs set MOQs to keep production efficient and cost-friendly. An MOQ helps them cover the cost of materials, labour, and machine setup. Huge orders also allow them to buy materials in bulk, which is lower in cost. MOQs help manage time, organise schedules, and keep the production line running perfectly.

How MOQs Differ For Custom Vs Standard Packaging

Standard packaging items, like plain brown boxes, often have lower MOQs. Our suppliers can produce them in bulk easily.

Custom packaging gives a higher MOQ to make it profitable. You pay more per unit for small custom runs.

|

Feature |

Standard Packaging |

Custom Packaging |

|

(MOQ)Minimum Order Quantity |

Mostly Lower ( e.g, 100 units) |

Mostly Higher (e.g, 500-1,000+ units) |

|

Setup Costs |

Low or None |

High (tooling, printing plates) |

|

Price Unite |

Higher for very low orders |

Lower at high volumes |

Key Factors That Influence MOQ In The UK

Key factors that influence MOQ in the UK include materials, production time, and order sizes. Unique packaging materials, as cardboard or plastic, have different prices, which can up or decrease the MOQ. Machine setup also affects MOQ because starting a production run takes time and money.

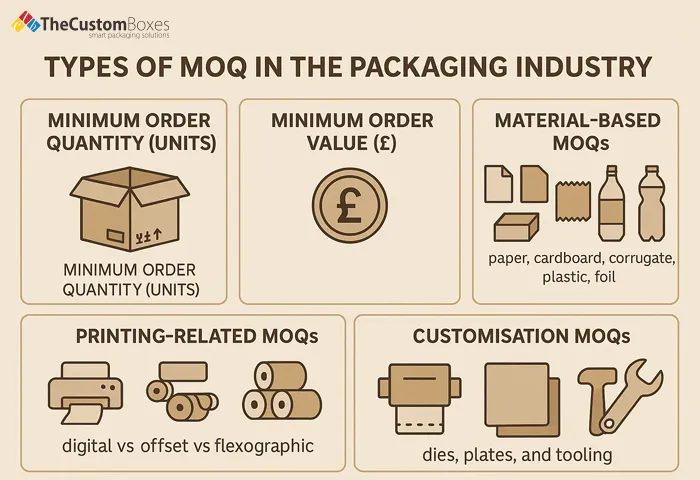

Types Of MOQ In The Packaging Industry

|

MOQ Type |

Description |

Key Focus |

|

Simple MOQ (Quantity) |

Requires a single minimum number of units (e.g, 500 boxes). |

Production Volume |

|

Simple MOQ (Value) |

Requires a minimum total spend e.g, £250 total order value. |

Total Order Revenue |

|

Complex MOQ |

Requires 2 or more conditions to be met (e.g, 1,000 units AND £500 minimum spend). |

Profit & Specific Materials |

|

High MOQ |

A large required order size. Often for custom, high-cost setup items. |

Lowers unit price greatly. |

|

Low MOQ |

A small required order size. Often for standard, less complex packaging. |

Great for tiny businesses or start-ups. |

Minimum Order Quantity (units)

The Minimum Order Quantity is 100 units. This means you must buy at least 100 products. You cannot order fewer than 100 items. It is the lowest number the seller accepts. This quantity helps the supplier manage their production costs efficiently. Your order needs to meet this 100-unit minimum.

Minimum Order Value (£)

MOV( Minimum Order Value) is £100. This is the advance price for your total order must cost. You cannot check out with a Total value less than £100. It's the lowest price the company will accept. This value helps cover their business expenses. Your sale total needs to reach the £100 limit.

Material-Based MOQs (Paper, Cardboard, Corrugate, Plastic, Foil)

The MOQ for materials such as paper, cardboard or corrugate, plastic, and foil is set by the supplier. MOQ is the smallest batch size they will design or sell. For custom packaging, it's often quite high. This is because setting up the machines for printing and cutting costs money.

Printing-related MOQs (digital vs offset vs flexographic)

- Digital printing has the lowest MOQ. You can often order just one unit. It is best for small batches or testing.

- Offset printing requires a medium to high MOQ, usually starting around 1,000 units, because it needs costly setup plates.

- Flexographic printing has the highest MOQ, often requiring 5,000 units or more. This method is most cost-effective for huge production runs due to its high initial setup costs.

Customisation MOQs: Dies, Plates, And Tooling

Customisation MOQs are often high. This is because of the initial costs for making things like dies, plates, and tooling. These are one-off expenses. The supplier must cover these setup costs, meaning they need a large order to make it profitable. You will see a lower unit price with a larger order.

Why Packaging Suppliers Require MOQ

Packaging suppliers require a Minimum Order Quantity to make their business viable. It helps cover setup costs for machines and printing. They need large orders to achieve economies of scale. This means it is cheaper per unit to produce thousands than just a few.

-

Production Efficiency And Setup Costs

Production efficiency increases with larger orders. Higher volumes allow suppliers to use machinery for longer periods. This spreads the initial setup costs over more units. Simply put, more items make each one cheaper to produce.

- Material Sourcing And Batch Manufacturing

Material sourcing means finding the good materials needed to make an item. Batch manufacturing means producing products in groups else than one by one. This helps save your time and money.

- Printing setup and machine time

Printing setup takes time and resources. Changing between jobs means the machine is idle. With a larger order, the machine runs for longer without stopping. This reduces waste and makes the overall process quicker per unit. The supplier uses this time efficiently.

MOQ Differences For Various Packaging Types

The Minimum Order Quantity differs widely by packaging kind. Standard, simple products. Basic folding cartons or labels mostly have a low (MOQ) of 100 units. More complex products as custom rigid boxes, glass bottles, or flexible pouches. Often have much higher MOQ, e.g, 500 to 10,000+ units. Due to specialised production needs.

Custom Boxes (Rigid, Corrugated, Folding Cartons)

Custom boxes arrive in multi types. Like Rigid, Corrugated, or Folding Cartons. They protect products and improve presentation. They help brands look professional and keep items safe.

- Typical MOQs For Custom Boxes in the UK

For folding cartons retail boxes, the MOQ is often as low as 100 units in the UK. Corrugated shipping boxes are mostly higher, sometimes 500 units or more.

Rigid boxes, luxury packaging usually start at 100 units. But often rise to 500 or more due to their complex structure.

- Why Customisation Increases MOQ

Customisation increases MOQ because of fixed setup costs. Suppliers need to make new dies or printing plates just for your design. These costs are higher and should be covered. A huge order allows them to spread this expense, making the unit price affordable.

Custom Bags & Pouches

Custom bags or pouches are designed to match your item’s size or shape, and style. Mostly businesses use them for food, beauty, and retail products. They also help brands stand out and appear expert to users.

- MOQs For Poly Mailers, Stand-up Pouches, Paper Bags

For poly mailers and paper bags, the MOQ often starts around 500 units for custom printing in the UK. Stand Up Pouches, which are more complex, generally have a higher MOQ, often starting at 1,000 units or more. Some digital printers offer lower MOQs, sometimes as low as 50 or 100 for simple logo.

Labels & Stickers

Labels and stickers share product info and show your brand. These are easy to use and arrive in many shapes. They make packaging look neat, clear, and more appealing to users.

- MOQs For Printed Labels Depending On Print Method

MOQs for printed labels change based on the print method used. Digital printing usually needs fewer labels, while flexo or screen printing needs more.

Inserts, Sleeves & Accessories

Inserts, sleeves, and accessories add extra support and style to packaging. They help protect products and improve presentation. These items fit around or inside boxes. They make packaging look neat, secure, and more appealing to customers.

- When Low-MOQ Or No-MOQ Options Exist

Low-MOQ or no-MOQ options exist for tiny companies and start-ups. These mostly involve digital printing on simpler packaging. Like mailer boxes or labels. You won't have the high costs of making printing plates.

How To Reduce MOQ In The UK Packaging Market

To reduce MOQ in the UK packaging market, talk to suppliers about small orders. Use simpler designs and standard materials. Combine orders with other products. Clear communication and flexibility with suppliers can lower costs and allow smaller, more manageable orders.

- Choosing Standard Sizes Instead OF Fully Custom

Choosing standard sizes is a great way to lower the MOQ. Suppliers already have the cutting tools and templates for these sizes. This avoids the one-off costs of custom dies and tooling. You only pay for the material and printing. This is much cheaper and allows for smaller orders.

- Avoiding Speciality Finishes That Require Higher MOQs

Avoiding speciality finishes can help keep MOQs low. Special finishes as embossing, foil stamping, or UV coating, often need huge orders. Choosing simple finishes reduces costs and production time.

- Working With UK-Based Low-MOQ Suppliers

Working with UK-based low-MOQ suppliers is often beneficial for small businesses. These companies usually use digital printing, which allows for much smaller order runs. Expect to pay a slightly higher unit price for this flexibility and speed.

Pros & Cons Of High Vs Low MOQ

High MOQ allows lower unit costs and a steady supply. But it requires more cost, more storage, and brings a higher risk. Low MOQ needs less cash and lowers risk, but unit prices are higher. Choose what suits your budget, space, and business needs best.

High MOQ Pros & Cons

High MOQ guarantees better unit pricing and significant savings from bulk buying. This sharply cuts your final cost. This ties up your capital and brings the risk of holding excessive, unsold stock.

- Better Unit Pricing

Better unit pricing is the main gain from a High MOQ. You get a much lower cost per item due to production efficiency and large discounts. This ties up capital and massively raises the risk of holding too much unsold stock.

- More Material And Finish Options

Offering more material and finish choices attracts a broader customer base. This flexibility can boost sales. Yet, it greatly increases manufacturing difficulty and production costs. Managing varied components and maintaining quality across many options becomes much harder.

- But Requires Higher Upfront Investment And Storage

This approach needs a higher upfront investment. You must pay a significant sum to the supplier initially. It also requires more storage space. Holding large quantities of stock means higher warehouse costs. Also, more complicated stock management.

Low MOQ Pros & Cons

Low MOQ needs less money upfront and lowers risk. It lets you test products and avoid large stock. But unit prices are higher, and choice can be limited. Restocks may be slower, too. Low MOQ suits small businesses. Yet it may cost more as you grow over the long term.

- Budget-Friendly For Start-Ups

This option is budget-friendly for start-ups. It demands a much lower initial payment, which helps conserve capital. You don't need extensive storage space either, saving on warehouse costs.

- Less storage, Low-risk Testing

This method needs less storage space. You save on warehouse costs by holding minimal stock. It allows for low-risk testing. You can try out new products without a huge financial commitment up front.

- But Higher Cost Per Unit And Fewer Customisation Options

But unit costs are higher, and customisation options are limited. Small orders give less choice and less power to negotiate. This can make products more expensive and less unique. It is easier to start, but harder to create fully personalised items at a low price.

How To Choose The Right MOQ For Your Business

Choose a Minimum Order Quantity that matches your budget, sales goals, and storage space. Think about demand and how fast you can sell the item. Pick a level that keeps the price low but still lets you meet users' needs without risk.

- Factors: Order Volume, Budget, Caling Plans, Storage

To choose the right MOQ, first look at your order volume. Checked your budget to see the cash you can commit upfront. Consider your future scaling plans and growth. Finally, assess your available storage space to comfortably hold the stock you buy.

- When To Choose High MOQs (growing brands)

Choose high MOQs when your brand is growing and sales are consistent. Bigger orders lower unit costs and help you keep stock ready. They also support smoother planning and faster scaling. High MOQs suit businesses with steady demand, enough storage space. Also, budget to invest in larger quantities.

- When Low MOQs Are Better (start-ups, trial batches)

Low MOQs are best for start-ups and trial batches. They need less money and reduce risk. You can test products, check demand, and avoid excess stock. Low MOQs give the best flexibility. Great for tiny businesses starting out.

MOQ in Sustainable & Eco-Friendly Packaging

MOQ is important for durable and nature-friendly packaging. Low MOQs help reduce waste and test new materials. High MOQs lower unit costs but need more storage. Pick an MOQ that matches your budget and Eco goals. This keeps your brand green while managing costs.

Why Eco Materials May Affect MOQ

Eco materials can raise MOQ because they cost more and are harder to get. Suppliers may need bigger orders to make production efficient. Balancing MOQ helps stay eco-friendly while controlling costs and stock.

Recycled Cardboard MOQs

Recycled cardboard MOQs are mostly higher for customers' orders. Preparation needs big orders to justify the setup costs of the wow printing or cutting equipment. This ensures the batch is price-effective for them. Standard, plain boxes often have a much lower MOQ for start-ups.

FSC-certified Material Availability

FSC-certified material availability varies. Some kinds are easily available. But others are harder to source. Manufacturers need to find good suppliers. This means they may have to wait longer or pay a premium for certain stocks.

Low-MOQ Options For Sustainable Brands

Sustainable brands can use stock packaging like standard boxes to get a low MOQ. Look for suppliers who hold ready-made FSC-certified options. Digital printing is another good choice for small. Custom batches without needing large orders.

Conclusion

MOQ, or minimum order quantity, is the smallest number of products a supplier will produce. It affects your costs, stock levels, and packaging options. High MOQ lowers the price per unit but requires more money and storage. Low MOQ is safer and flexible but more expensive per item.

The Custom Boxes give the best MOQ that fits your budget, demand, and business goals. Start small to test new items. Balance cost per unit with risk. Choose an MOQ that keeps stock manageable and supports business growth. Start with small orders to reduce risk. Such as testing new designs and materials easily. Receive good solutions that fit your budget, fulfil your needs, and help your business grow quickly.

Frequently Asked Questions

What Is MOQ In Custom Packing?

MOQ in custom packing is the minimum number of products a supplier will produce. It affects cost, stock, and how you plan your orders.

What Is The Purpose Of MOQ?

The purpose of MOQ is to help suppliers manage production efficiently. It also sets the minimum order you must buy, affecting cost and stock.

What Does FOB And MOQ Mean?

FOB means free on board, showing who pays shipping and when goods are transferred. MOQ is the Minimum Order Quantity a supplier requires for production.

What Is The Minimum Order Quantity Requirement?

The MOQ requirement is the smallest number of units a supplier will sell of an item. It helps control prices and keeps production efficient.

Is MOQ Negotiable?

Yes, the Minimum Order Quantity is typically negotiable. Suppliers may be flexible, especially if you build a stronger relationship with them. Try to allow a higher price per unit or agree to a longer contract in exchange for a lower initial order volume.

Can MOQ Be Reduced For Startups?

Yes, MOQ can often be reduced for start-ups if you negotiate. Small orders may cost more, but they lower the risk and help you begin.